|

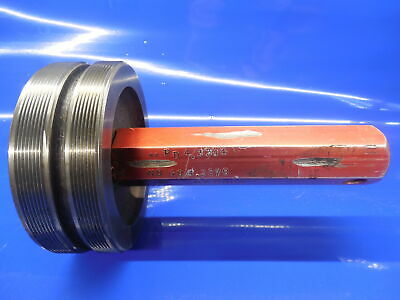

TT/TZ/ZT/ZZ校对规

进口TT/TZ/ZT/ZZ校对规

品牌:Vermont Gage

产地:美国

进口螺纹量规、惠州Vermont Gage量规

广州Vermont螺纹规、西安vermont Gage螺纹规

Most times, you have to rely on an individual’s sense of “good feel”, “good fit”, or amount of “shake”, to set an adjustable ring gage with a truncated setting plug gage. And sometimes the accuracy of human judgment is highly debatable…especially if you’re looking at hundreds of rejected parts.

A HILO setting plug gage provides optimum ring gage accuracy, without subjective human judgments for “fit”, “feel”, or “shake”. It only relies on an inspector to turn it into the thread ring, and then helps the inspector make foolproof adjustments. Here’s how:

First, the adjustable ring is set so it can be threaded onto the LO pitch diameter. The second or HI pitch diameter portion indicates that the setting is too high if the ring gage can be threaded on to it more than 1½ turns. The setting is correct when the adjustable ring gage can be threaded only onto the LO pitch diameter portion, but not more than 1½ turns on the HI. It’s that simple!

–

Prolongs Ring Gage Life: How many gages has your company scrapped or sent to be reconditioned because the “feel”, “fit”, or “shake” wasn’t right? HILO set plugs can tell you without a doubt when flanks are excessively worn, or too much “bellmouthing” has affected the accuracy of your gage. Plus, since HILO plugs are designed for the full use of the pitch diameter tolerance, you can often discover additional tolerances in thread rings that couldn’t be found with conventional set plug gages.

More Than Just a Setting Plug: HILO is the only plug gage available with the HI and LO portions ground and lapped with identical lead and angles. That means you can use a HILO plug gage to perform positive and dependable wear checks on solid ring gages too.

HILO Thread Setting Gages For Standard and Special Threads: HILO master setting plug gages are designed to precisely size and check minimum and maximum tolerances of adjustable and solid type threaded ring gages. They’re also ideal for checking flanks and angles for wear, and to determine excessive “bellmouthing”. Each gage is engraved to indicate: size, threads per inch, thread type, and minimum pitch diameter limit for quick identification.

For Highly Accurate Adjustable Ring Gage Settings: HILO set plugs take the guesswork out of setting high and low tolerances on adjustable thread ring gages. These unique setting plugs are designed with two different thread pitch diameters. The front portion is the low tolerance limit, and the back portion is the high tolerance limit. By adjusting the ring gage so it will thread onto the front portion without threading more than 1½ turns onto the back portion, a precise setting is achieved.

Worn Flank Checks: The back portion, or high limit end of each HILO gage has the outside diameter of the thread truncated in accordance with ANSI/ASME B1.2, latest edition. It automatically furnishes a check on worn flanks similar to, but more exacting than, standard truncated setting plug gages.

Angle Checks: In addition, HILO setting plugs can also provide a precise angle check on ring gages because of the high limit pitch diameter, and the low outside diameter on the back portion of the plug. Any worn flanks or angles will be indicated when the ring gage fits snugly on the low pitch diameter portion, and enters the high pitch diameter portion more than 1½ turns.

“Bellmouthing” Inspection: The amount of excessive ring gage “bellmouthing” can be determined by the number of turns required for the high pitch diameter portion to enter the ring. If the high portion does not enter the ring, the ring is within tolerance.

Solid Ring Gage Checks: Since the HILO setting plug has the low and high limit portions ground and lapped with identical leads and angles, the low and high limits on solid gages can be easily and accurately checked. The HILO plug design provides a completely positive and dependable wear check, and allows for full utilization of the pitch diameter tolerance inside the ring in accordance with ANSI/ASME B1.2, latest edition.

Manufacturing Standards

Material: High Speed Steel (Up to 1 ½” Diameter)

LO Pitch Diameter Tolerance (Minimum Ring Pitch Diameter Tolerance): ± 0.00005”

HI Pitch Diameter Tolerance (Maximum Ring Pitch Diameter Tolerance): + 0.0001”

Lead & Angles: W Tolerance

Major Diameter Back Portion (HI): Truncated per ANSI/ASME B1.2 (Class X)

Major Diameter Back Portion (LO): Full Form (Class X)

Straightness & Taper: ANSI/ASME B1.2, Latest Edition

中国的螺纹环规都是通过校对规来检测是否合同,同时亦可以通过扫描仪和测长机来检测,但是使用校对规检测的效率会大大的提升,且准确可靠。

相对于美国的TT/TZ/ZT/ZZ来说,就是HI-LO,极大数值与极小数值做成的量规来检测螺纹环规,包括来检测美国的固定环规。vermont可以生产各类HI-LO量规,欢迎您来咨询。